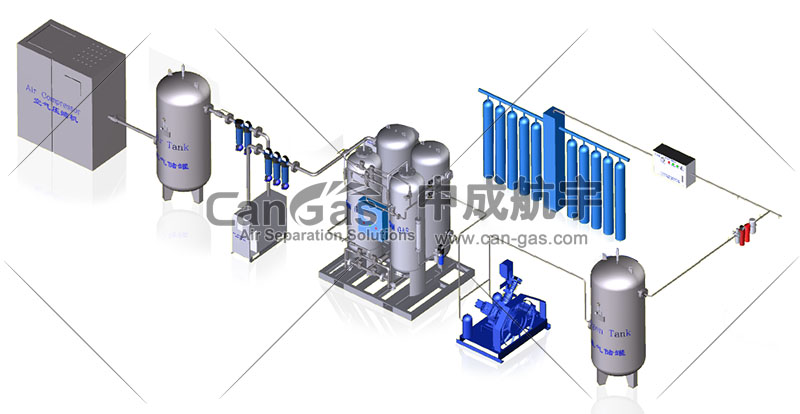

A complete oxygen production system consists of an air compressor, an air dryer, air filter group, PSA oxygen generator, oxygen filter group, oxygen booster, oxygen storage tank and intelligent control system.

Air compressor

1. It is recommended to use oil-free air compressor, which can effectively increase the service life of the system.

2. The rated discharge pressure the air compressor is recommended to be 0.7-0.9MPa. Excessively high or low discharge pressure is not good.

3. When the user jobsite altitude is ≥500m, the atmospheric pressure drop must be considered when the model of air compressor is selected.

4. The oil content in the compressed air discharged from the air compressor must be ≤10ppm.

Compressed air pretreatment equipment (refrigerated air dryer, desiccant dryer, filter group)

1. Before the compressed air enters the oxygen generator, the process of water removal, oil removal, dust removal, etc. must be carried out, because the poor purification of the compressed air directly affects the service life of the zeolite molecular sieve.

2. Adsorption dryer or refrigeration dryer can be used to remove water from compressed air.

3. To remove impurities from compressed air, use multi-stage filters with different types and different filtering precisions depending on the situation. The product oxygen gas produced can also be refiltered as required to ensure the user's gas usage requirements.

Oxygen generator

1. Confirm whether the adsorption pressure is between 0.45 and 0.55.

2. The flow of flowmeter of the oxygen generator should not exceed the rated flow.

3. It is forbidden to adjust the ball valve from which the handles are removed on the oxygen generator. The pressure reducing valve cannot be replaced without authorization.

4. Drain water once a day from bottom of the air buffer tank of the oxygen generator.

5. After the system is powered off or the MCB and cables are replaced, please pay attention to the running direction of motors when restarting the equipment.

6. Do not use water, oil and chemicals to clean the system pipes.

Oxygen booster

Through the oxygen booster, the produced oxygen pressure can be boosted to the value wanted.

Oxygen storage tank

The oxygen storage tank can ensure continuous and stable supply of oxygen to user from the entire system.

Intelligent control system

1. Remotely monitor the operating status of the oxygen production system, debug and upgrade the controlling of oxygen production system.

2. Store data for inquiries at any time.

3. Remote maintenance of oxygen generator and modification of data.

4. Remote start and stop oxygen generation system.

Advantages of PSA oxygen generator

1. The unit is simple.

2. The requirements for molecular sieves are relatively low, and for the same oxygen production requirement, the amount of molecular sieves needed is smaller.

3. The equipment is small in size and the cost is relatively affordable.

4. The requirements for the degree of automation of the entire equipment are relatively low. The air compressor and air dryer can be started and stopped separately from the oxygen generator, or can be linked to control.