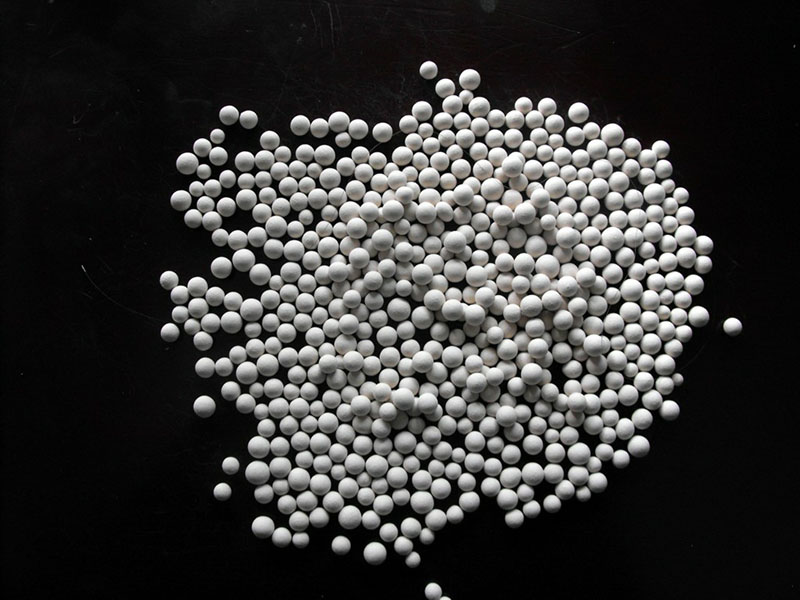

Molecular sieve is the most important gas separation material in oxygen generator or nitrogen generator, but it can not be used all the time. It has a certain service life too. It needs to be replaced when it reaches or exceeds this time to ensure the gas purity of oxygen or nitrogen generator.

The service life of molecular sieve is usually determined by four points: the first is the grade of molecular sieve, the second is the service environment (affected by moisture and oil pollution), the third is the compactness of filling, and the fourth is regular maintenance. The higher the grade of molecular sieve, the longer the service life. Dry and oil-free environment can also ensure the maximum service life of molecular sieve. Of course, there are also factors of appropriate filling density & regular maintenance.

According to the actual assembly experience of CAN GAS, under standard working conditions and regular maintenance of all parts, the service life of ZMS (oxygen making zeolite molecular sieve) molecular sieve is 5 ~ 8 years and that of CMS (carbon molecular sieve for nitrogen making) is 6 ~ 10 years. The feed air quality has the greatest impact on the performance of molecular sieve, so the moisture in the feed air must be minimized.

In a word, the service life of molecular sieves can be prolonged as long as they are used scientifically and maintained well. For example, one PSA oxygen generator plant in Bangladesh, which was made by CAN GAS, has been working for more than 13 years without replacing any molecular sieve.