We Pride Ourselves on Providing

More than 10,000+ Units of CanGas® Onsite Gases Systems

Comprehensive gas application solutions across chemicals, healthcare, and more

Oxygen Generator

With rich field experiences, excellent products and services, unique designs PSA/VPSA technology, CanGas® series standardized PSA oxygen generators CAPO 93±3%, CAPO Plus Premium 95±1%, CAPO HP Ultra High 99±0.5%, SMART-C, CAP-O/C, CARO, CAVSA, CAVO, CFS were developed to meet all levels of customer requirements globally.

Read More

Nitrogen Generator

CanGas® series PSA/membrane nitrogen generators CAPN, CAPN HP, CAME, SMART-SC, HPNGU, CAC, and nitrogen purifiers CAY, CAW, CAU, which were CE & ISO9001/14001/45001... certified to follow international industrial Standards & Regulatory, are installed in all over the world till now in various industries with wonderful performance & market feedback.

Read More

Oxygen Enrichment System

This system efficiently and sustainably generates high-concentration oxygen, enhancing oxygen supply in hypoxic environments. It effectively alleviates altitude sickness, ensuring comfort and safety in high-altitude regions.

Read More

Medical Gas System

We offer customized medical gas systems for healthcare institutions, delivering high-purity oxygen that meets international medical standards. Our products are safe, reliable, and seamlessly integrate with medical environments.

Read More

Gas Recovery and Purification Equipment

Designed for sustainability, this equipment recovers and purifies valuable gases (e.g.,CO2, hydrogen) from industrial exhaust streams. It reduces waste, lowers operational costs, and supports circular economy practices across industries.

Read More

Associated Equipment

Our robust compressors and accessories ensure optimal performance for systems. Engineered for durability and precision, they support efficient air/gas compression, system control, and long-term reliability.

Read More

WHO WE ARE

CAN GAS Core Business Includes

● Industrial nitrogen and oxygen generators and systems

● Medical oxygen generators and systems

● Artificially atmospheric environment engineering and systems

Established in 1998, CAN GAS SYSTMES COMPANY LIMITED, a reputable manufacturer of on-site nitrogen and oxygen plants and various gases system.

-

10000

Sets ofEquipment Systems

-

120

MultipleCountries Distributed

-

1998

Year ofEstablished

-

28000

m²Factory Occupied Area

CAN GAS Advantage

As Manufacturer and Exporter with 30 Years Experience in Air Separation Field

-

10 years of worry free operation

-

Leading technology, secure and stable

-

Energy saving and efficient, an economical choice

-

One click operation, fast gas production

-

Low energy consumption, pollution-free

-

Customized gas solutions to match your needs

Application cases in pulp & paper mills

Oxygen application

Pulp & paper mill

Now oxygen is widely used in paper and pulp industry as oxygen bleaching for environmental protection. Because oxygen is non-toxic gas and doesn’t pollute the environment, the bleaching agent and bleaching waste water can be reduced by 50% after oxygen delignification.

Read More

Business Partner

Curated accessories from globally renowned brands, committed to superior quality

News

Read More-

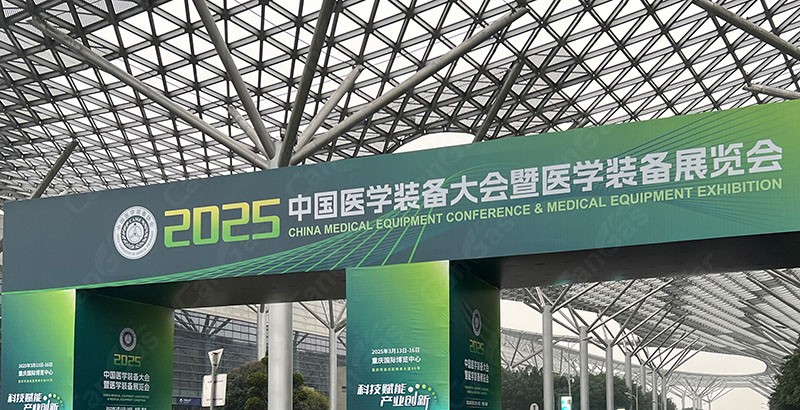

CAN GAS Debuts at the 2025 China Medical Equipment Conference

2025-05-14 14:16:41 Company News -

Spring CMEF, CAN GAS Invites You to the Medical Industry Event in 2025

2025-05-14 14:12:22 Company News -

Unveiling the Mystery: Why Do PSA Nitrogen Generation Systems Have Varying Service Lives

2025-05-14 13:59:47 Technical Articles -

Is It Necessary to Equip Pet Hospitals with PSA Oxygen Generators

2025-05-14 13:45:25 Technical Articles -

How to Deploy High-Altitude Diffusion Oxygen Systems

2025-05-14 13:40:39 Technical Articles