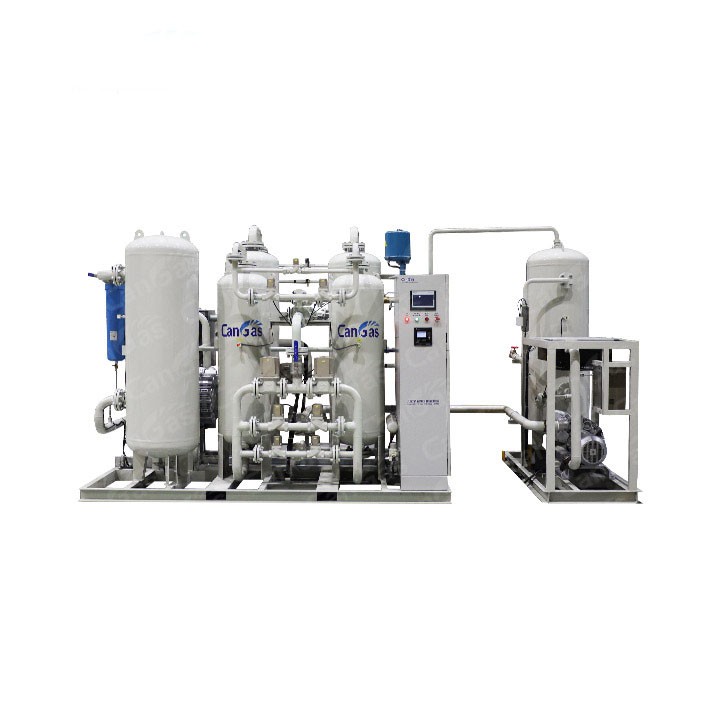

CO2 Recovery and Purification System

Gas Recovery and Purification Equipment

Product Introduction

CanGas® CA-CDP series flue gas recovery and purification CO2 system separates CO2 from other components such as O2, N2 and other impurity components to obtain CO2 product gas via the PSA process. The dehydrated raw gas enters the PSA-CO2 purification unit, and the un-adsorbed tail gas is discharged from the top of the adsorption tower. After a certain time, the qualified CO2 in the adsorption tower enters the product gas storage tank and comes to the gas point or other storage device, and part of the CO2 product gas returns to the PSA-CO2 device.

Specifications

- 70% V/V customizableCO2 Purity

- 3~200Nm³/h customizableCO2 flow

- 1.3-1.6kW/m³Power

Core Advantage

Quick startup and stable

This device can be deployed as soon as the mixed gas is connected on site, and qualified product CO2 can be made in 10-20 minutes after startup.Adjustable CO2 concentration

The system can produce 70% CO2 gas as required, and ≥ 90% purity CO2 can be made through the secondary purification device.Adjustable product gas volume

3-200Nm³/h (high flows rates can be customized at demand).High degree of automation

This system adopts PLC automatic control system and can be automatically operated according to the product gas volume and concentration requirements, 7/24 unattended.

CAN GAS not only escort the machine, but also is committed to becoming a long-term trusted strategic partner. Together to create an outstanding, reliable and sustainable industrial future.

Application Scenario

CanGas® After-sales Service Content

CAN GAS not only escort the machine, but also is committed to becoming a long-term trusted strategic partner,Together to create an outstanding, reliable and sustainable industrial future.

On-site service

Relocation service

Remote Services

Renovation services

Quality assurance service

Spare parts service

Upgrade service

Maintenance service

Oxygen purity(%)

Optional

- 90

- 93

- 96

- 99

Oxygen flow(m³/h)

Optional

- 0

- 200

Oxygen pressure(bar)

Optional

Delivery type

Methods

Nitrogen purity(%)

Optional

- 90

- 93

- 96

- 99

Nitrogen flow(m³/h)

Optional

- 0

- 200

Nitrogen pressure(bar)

Optional

Delivery type

Methods