Benefits of Molecular Sieve Pressure Swing Adsorption (PSA) Nitrogen Generator as an Auxiliary Gas Supply for Laser Cutting

ReturnBenefits of Laser Cutting with Nitrogen

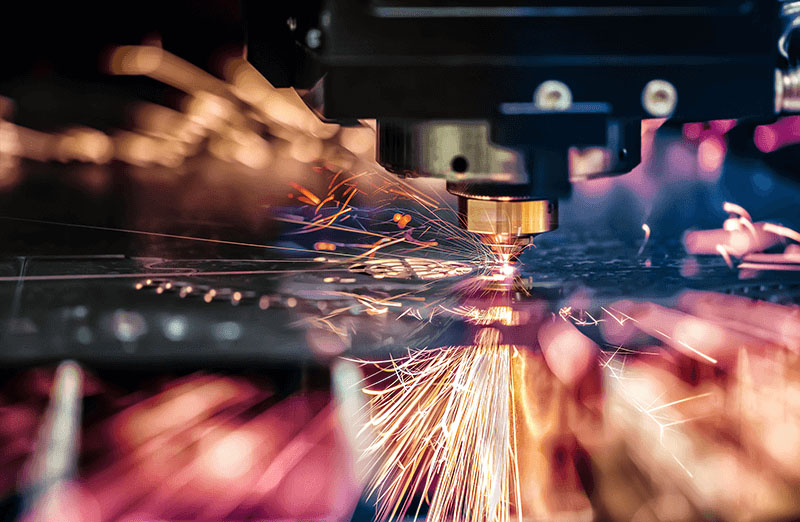

1. Prevent oxidation: Due to its inert properties, nitrogen gas allows the laser to operate in an oxygen-free environment without the risk of oxidation. When your app heats up and comes in contact with oxygen, a phenomenon called oxidation occurs. This can cause a carbon layer to form on the cut edge, leading to issues such as poor product finish and adhesion problems with any coatings or paints applied to the oxidized surface.

2. Helps clear the laser beam: To prevent beam distortion and maintain power and intensity, the beam path needs to be cleared of dust particles and any other contaminants that could cause it to diverge or lose power. Nitrogen is the ideal medium for purging beam guides because it is dry, clean, oil-free and has very low levels of contaminants.

Benefits of Using a Nitrogen Generator to Get Nitrogen

1. Lower cost: The use of nitrogen as auxiliary and purge gas is the bulk of the cost of laser cutting, especially for fiber lasers. Therefore, producing nitrogen yourself can reduce the cost of laser cutting.

2. Efficient and convenient nitrogen production: The PSA nitrogen generator can run continuously without too much attention from personnel.

3. Better control: Self-produced nitrogen means no need to order and replace nitrogen cylinders. No more late deliveries disrupting production, and no more worrying about unpredictable price increases from suppliers.

4. Highest efficiency: No oxidation edge, can provide 99.999% high-purity nitrogen.

5. Gas on demand: This plug-and-play solution is sized to match your laser cutter, so you don't have to empty and refill bottles in valuable production time.

6. Using the nitrogen cylinder filling system, the produced nitrogen can be stored in the gas storage tank. This type of system is ideal for intermittent use or where demand fluctuates widely. Typically, contract laser cutting job shops will benefit from this type of installation.