Will the pressure of PSA nitrogen production system affect the adsorption effect?

ReturnPSA nitrogen generator, also called pressure swing adsorption nitrogen generator, its working principle is to separate oxygen and nitrogen in the air through the microporous structure of carbon molecular sieve, and produce product nitrogen.

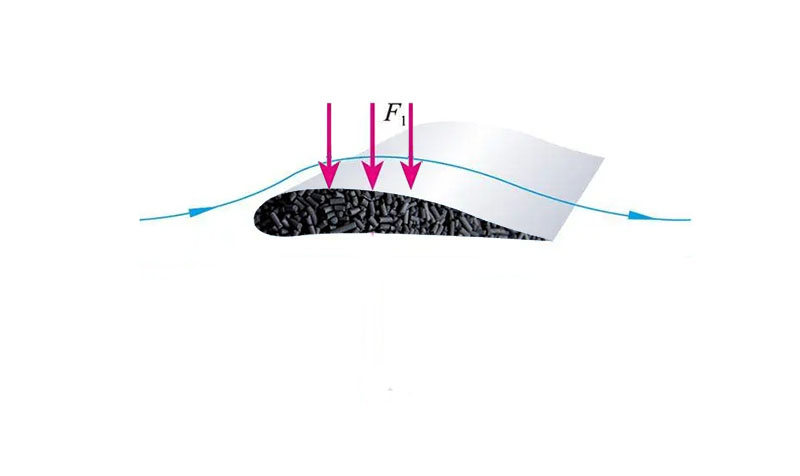

There are two main core processes of PSA nitrogen generator, pressure adsorption and pressure reduction analysis. The entire process can be summarized as: pressurization, gas production; pressure equalization; pressure reduction, exhaust; then pressurization, gas production... a continuous cycle of several stages. From the process flow, we can know that the carbon molecular sieve has a very close relationship with the pressure when separating nitrogen. The adsorption capacity of the carbon molecular sieve to the adsorbed gas will be different under different pressures. When the adsorption equilibrium is reached, the same gas will be adsorbed. The higher the pressure, the greater the adsorption capacity of the adsorbent; conversely, the lower the pressure, the smaller the adsorption capacity. Therefore, the pressure will affect the adsorption effect. Of course, the relationship between the two is not completely linear. Regarding the pressure under which carbon molecular sieve is more suitable, several factors need to be considered comprehensively. It is generally believed that the working pressure for carbon molecular sieves is within the pressure range of 7 to 9 bar, the PSA nitrogen generator can achieve better gas production rate and lower air consumption.