Summary of causes for automatic valve failure in PSA nitrogen generation system

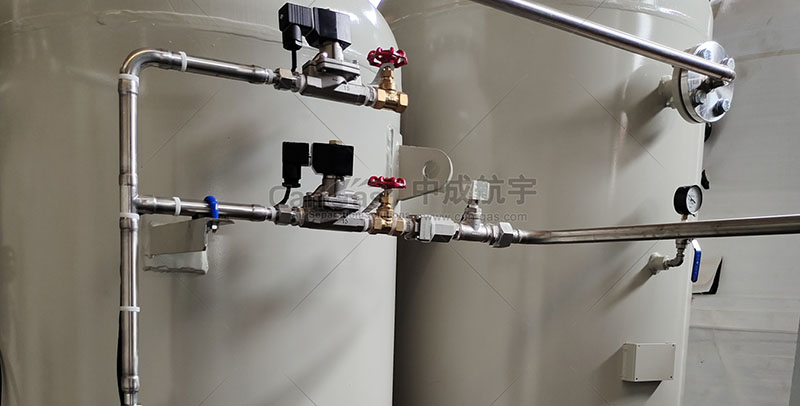

ReturnThe automatic valve in the PSA nitrogen generation system controls the on-off and gas flow direction. When the automatic valve fails, it may appear that medium and low pressure gas blow-by, increase in air flow or decrease in air pressure in the PSA nitrogen production system.

Based on long-term professional experience, we have summarized several common causes of automatic valve failure;

1) The automatic valve is frozen or stuck by other articles. When there is a small amount of impurities on the sealing surface, it will also cause the valve not to close tightly.

2) The automatic valve seat fixing bolts are not tightened evenly, causing air leakage from the gaps in the gasket. If left alone, the leakage will become larger and larger later.

3) The valve stem falls off because of following reasons: broken fixed cotter pin, loose nut, falling off, broken spring, etc.

4) The fixing bolt fell off, causing the entire automatic valve cylinder to fall off and the valve does not work.

5) The valve stem is broken. The main reason is poor stem material. Or the spring is too hard, and the valve stem is stressed too much during the opening and closing process of the valve.

6) The gap between the valve stem and the valve seat hole is too small, causing it to get stuck.

When we find that the automatic valve has the above conditions during routine maintenance, we should immediately stop it temporarily for maintenance.