What is the appropriate size of the air buffer tank in PSA nitrogen production?

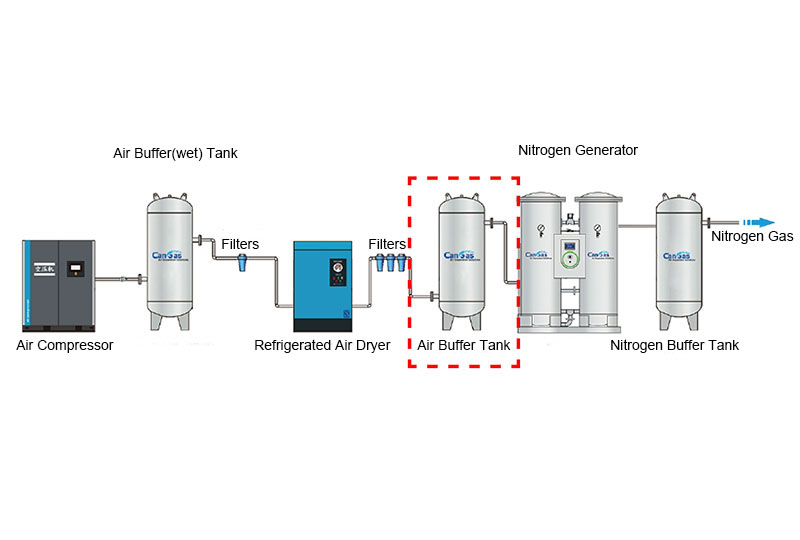

ReturnIn the PSA nitrogen production system, in order to protect the air compressor better, ensure stable compressed air pressure, and ensure that the loading and unloading of the air compressor is within a reasonable range, CAN GAS recommends an air buffer tank after the air compressor.

As for the appropriate size of the air buffer tank, it requires rigorous calculation.

Taking a common screw air compressor as an example, when the size of the buffer tank is not suitable for the air compressor, it will lead to frequent loading and unloading of the air compressor, and an increase in the number of opening and closing of the air inlet valve.

Calculating the volume (V) of the appropriate buffer tank can be done by the following formula: (Note: The formula is provided by Atlas series air compressors (Wuxi Atlas, Liutech, Bolite), and its minimum loading and unloading interval is 30s.)

V≥Loading rate×(1-Loading rate)×Rated flow rate of air compressor×Atmospheric pressure×Air outlet temperature/(2×Loading and unloading pressure difference×Air inlet temperature)

In the above formula, the meanings of each parameter are as follows:

Loading rate: actual air consumption/air compressor rated air volume;

Rated flow rate of air compressor: unit is m3/min;

Air outlet temperature and inlet temperature: Kelvin temperature (K);

The working pressure of the buffer tank: should be greater than the maximum pressure of the compressed air.

It can be seen that before calculating the volume of the buffer tank, it is necessary to confirm the volume and loading rate of the buffer tank, air compressor flow rate, set pressure difference, atmospheric pressure at the place of use, ambient temperature and other values; if the interval between loading and unloading of the air compressor is long, the volume of the buffer tank should also be increased accordingly.