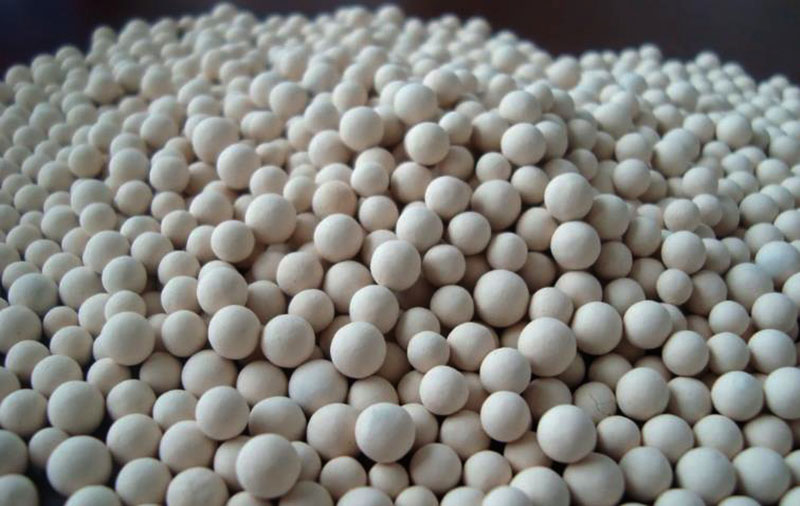

The molecular sieves used in PSA oxygen production system are artificially synthesized crystalline aluminum silicates. In addition to artificial ones, there are also natural molecular sieves, commonly known as zeolites.

There is actually not only one type of molecular sieve. There are many types. The main types currently used are A, X and Y. Each type has different pore sizes and properties according to its cations, which has led to more sub-categories, such as 3A, 4A, 5A, 10X, 13X and other models.

The cavities in the molecular sieve account for about 50% of the volume, and the average internal surface area per gram of molecular sieve is 700-800m2. The oxygen production adsorption process occurs inside the cavities, which can absorb specific molecules smaller than the cavities into the cavities and block molecules larger than the cavities outside the cavities, playing a screening role. There are far more materials with porous structures than zeolite molecular sieves. The reason why zeolite molecular sieves are chosen to participate in PSA oxygen production is that they have the following characteristics;

1) Strong adsorption and good selective adsorption performance.

2) Large adsorption capacity, the amount of finished oxygen with the same flow purity will be relatively small.

3) Easy to analyze and regenerate

4) Good stability, can still maintain normal adsorption capacity below 200℃.

5) The service life of the molecular sieve is also relatively long. Under normal use, it can continue to work for 5-8 years

Since PSA oxygen production belongs to normal temperature oxygen production in the field of air separation, 5X molecular sieve is generally used.