In PSA oxygen production systems, flanges are common and important components that can connect pipelines and withstand greater pressure.

People familiar with flanges may know that when flanges are connected, the pipelines, pipe fittings or equipment need to be fixed on a flange plate first, and then the flange gaskets are added between the two flange plates and bolted together to complete the connection. Although the flange gaskets here look inconspicuous, they are made of many materials. If you want to ensure the safety of oxygen production, you must choose the right flange gaskets.

First of all, the gaskets of oxygen pipeline flanges must be non-flammable substances without grease. Secondly, according to the size of the pipeline pressure, choose the appropriate gasket material, specifically;

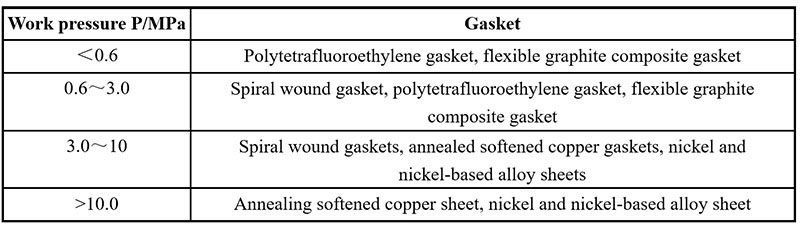

When the working pressure of the pipeline is less than 0.6 MPa, the gasket should be a polytetrafluoroethylene gasket or a flexible graphite composite gasket; when the pressure is between 0.6 and 3.0 MPa, you can use a wound gasket, polytetrafluoroethylene gasket, or a flexible graphite composite gasket; when the pressure is between 3.0 and 10 MPa, you can use a wound gasket, annealed and softened copper gasket, nickel, and nickel-based alloy sheet; when the pressure is greater than 10.0 MPa, you need to use annealed and softened copper sheet, nickel, and nickel-based alloy sheet.

Choosing the right flange gasket can effectively enhance the sealing performance of the oxygen pipeline and ensure that there is no leakage in the pipeline. Therefore, the selection of gaskets is of great significance to the safety and performance of the entire oxygen production system.

Table: Gaskets for oxygen pipeline flanges