The storage of medical oxygen gas shall be in a special room, and its plane layout, fire resistance rating of buildings, safe passage and fire protection shall comply with the provisions of “Code for Fire Protection Design of Buildings” (GB 50016). The lightning protection of the central oxygen supply station shall comply with the provisions of “Code for Design of Lightning Protection of Buildings” (GB 50057), and the impulse grounding resistance shall not be greater than 30 Ω. The electrical facilities in medical oxygen and medical nitrous oxide storage rooms shall be explosion-proof.

The central oxygen supply station shall not be located in underground or semi underground buildings or floors.

The central oxygen supply station should be arranged as an independent single storey building, and the fire resistance rating should not be lower than Grade II. If it is adjacent to other building structures, the adjacent wall should be a firewall without doors, windows and holes, and must have a door that leads to the outside directly. The doors and windows on the enclosure shall be opened outwards and shall not be made of wood, plastic steel and other combustible materials.

The central oxygen supply station shall ensure good ventilation, and the air exchange rate shall not be less than 8 times/hour.

Design and installation of central oxygen supply pipeline

1. Design requirements

1.1. The gas flow velocity of oxygen pipeline shall not be greater than 10m/S;

1.2. The installation position of oxygen terminal shall be convenient for use, and the recommended height is 1.3-1.5m from the ground;

1.3. The design pressure of the pipeline shall comply with the relevant provisions of the “Code for Pressure Piping - Industrial Piping - Part 3: Design and Calculation”;

1.4. The design flow at the terminal of the central oxygen supply system shall comply with “GB50,751 Technical Code for Medical Gas Engineering”.

2. Installation technical requirements

2.1. Personnel engaged in the installation of oxygen pipelines and equipment must understand the characteristics of oxygen, master the pipe network process, and apply the indicators of this standard;

2.2. Pipeline welding requirements.

2.2.1 Argon arc welding is adopted for stainless steel pipe;

2.2.2 The pipe welds shall be visually inspected and conform to the welding quality standards.

3. Inspection before pipeline installation

3.1 Degreasing shall be carried out before pipeline installation, and there shall be no oil stain pollution;

3.2 All kinds of oxygen valves must have valid product inspection certificates or pass the valve sealing test before being installed on the pipeline.

4. Pipeline leakage test

4.1 The leakage test of medical gas pipeline shall be carried out by subsections, sections and the whole system;

4.2 The test shall be conducted with nitrogen or oil-free compressed air for 24h, and it shall be qualified if it meets the relevant specifications.

5. Pipes in concealed works

The pipes installed in the concealed works must be inspected and qualified before the installation of the next process.

6. Other requirements for pipeline installation shall be in accordance with “GB50235 Code for Construction of Industrial Metallic Pipeline Engineering”and “GB50236 Code for Construction of Field Equipment and Industrial Pipeline Welding Engineering”.

Requirements for central oxygen supply system

1. The supply source of medical molecular sieve oxygen generator and the quality of its product gas shall meet the requirements from relevant national administrative departments.

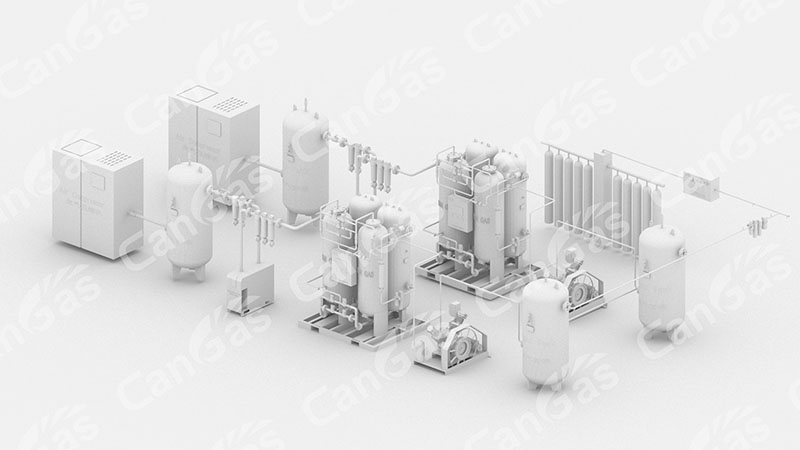

2. The medical molecular sieve oxygen generation unit should be composed of air compressor, air storage tank, drying equipment, molecular sieve O2 generator, oxygen storage tank, etc. If necessary, it should include booster.

3. The exhaust port of molecular sieve generator shall be equipped with muffler.

4. The medical molecular sieve oxygen generator unit shall be equipped with operation monitoring, oxygen concentration and moisture, carbon monoxide impurity content monitoring and alarm systems.

5. Backflow prevention measures shall be taken for each supply branch of the supply source of medical molecular sieve oxygen generator, and gas sampling port shall be set at the outlet of the supply source.

6. The main supply source medical molecular sieve oxygen generator, standby or standby combined gas source shall meet the peak oxygen consumption of medical and health institutions.

7. When the oxygen concentration of the unit is lower than the specified value or the impurity content exceeds the standard, and the real-time detection facility fails, the medical molecular sieve oxygen generator shall be automatically isolated and switched to the standby or emergency standby oxygen source.

8. Medical and health institutions shall not set up a system for filling the gas produced by the medical molecular sieve oxygen generator into the high-pressure cylinder.