Cutting, Welding

Oxy-fuel combustion is the process of burning a fuel using pure oxygen instead of air as the primary oxidant. If the nitrogen component of air is not heated, the consumption of fuel would be reduced, which makes higher flame temperature possible.

Oxy-fuel combustion is the process of burning a fuel using pure oxygen instead of air as the primary oxidant. If the nitrogen component of air is not heated, the consumption of fuel would be reduced, which makes higher flame temperature possible.

Historically, the primary use of oxy-fuel combustion has been in welding and cutting of metals, especially steel, as oxy-fuel affords a higher flame temperature than normal air-fuel.

Oxy-Fuel Welding (commonly called oxyacetylene welding, oxy welding, or gas welding in the worldwide) and Oxy-Fuel Cutting are a process of using fuel gas (or liquid fuels, e.g. gasoline) and oxygen to weld or cut metals.

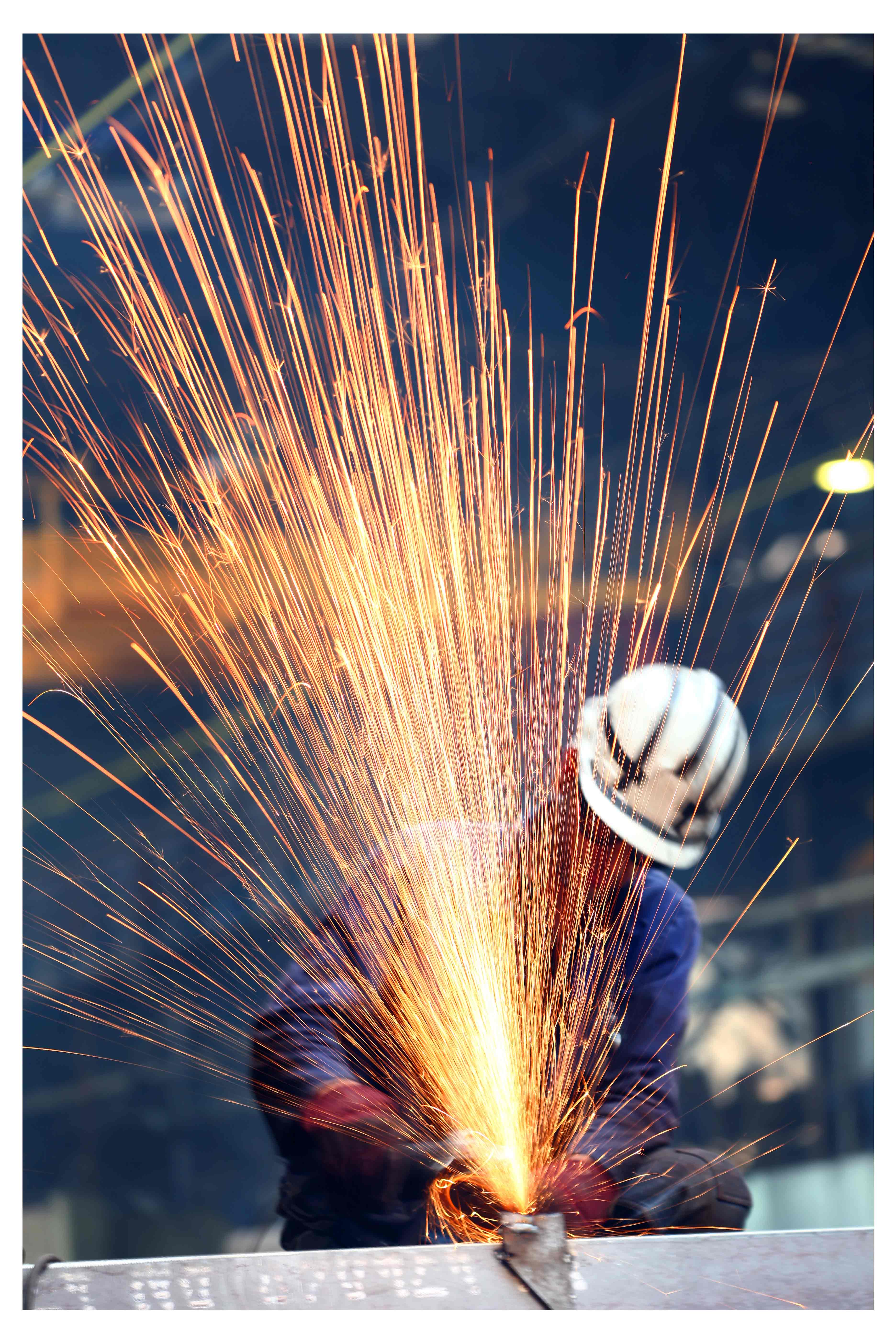

In oxy-fuel welding, a welding torch is used to weld metals. When two parts of metal are heated to a same temperature, there will be a shared pool of molten metal, then the metals could be welded together well. The molten pool generally with additional metal are together called filler. Filler material to be used depends upon the metals to be welded.

In oxy-fuel welding, a welding torch is used to weld metals. When two parts of metal are heated to a same temperature, there will be a shared pool of molten metal, then the metals could be welded together well. The molten pool generally with additional metal are together called filler. Filler material to be used depends upon the metals to be welded.

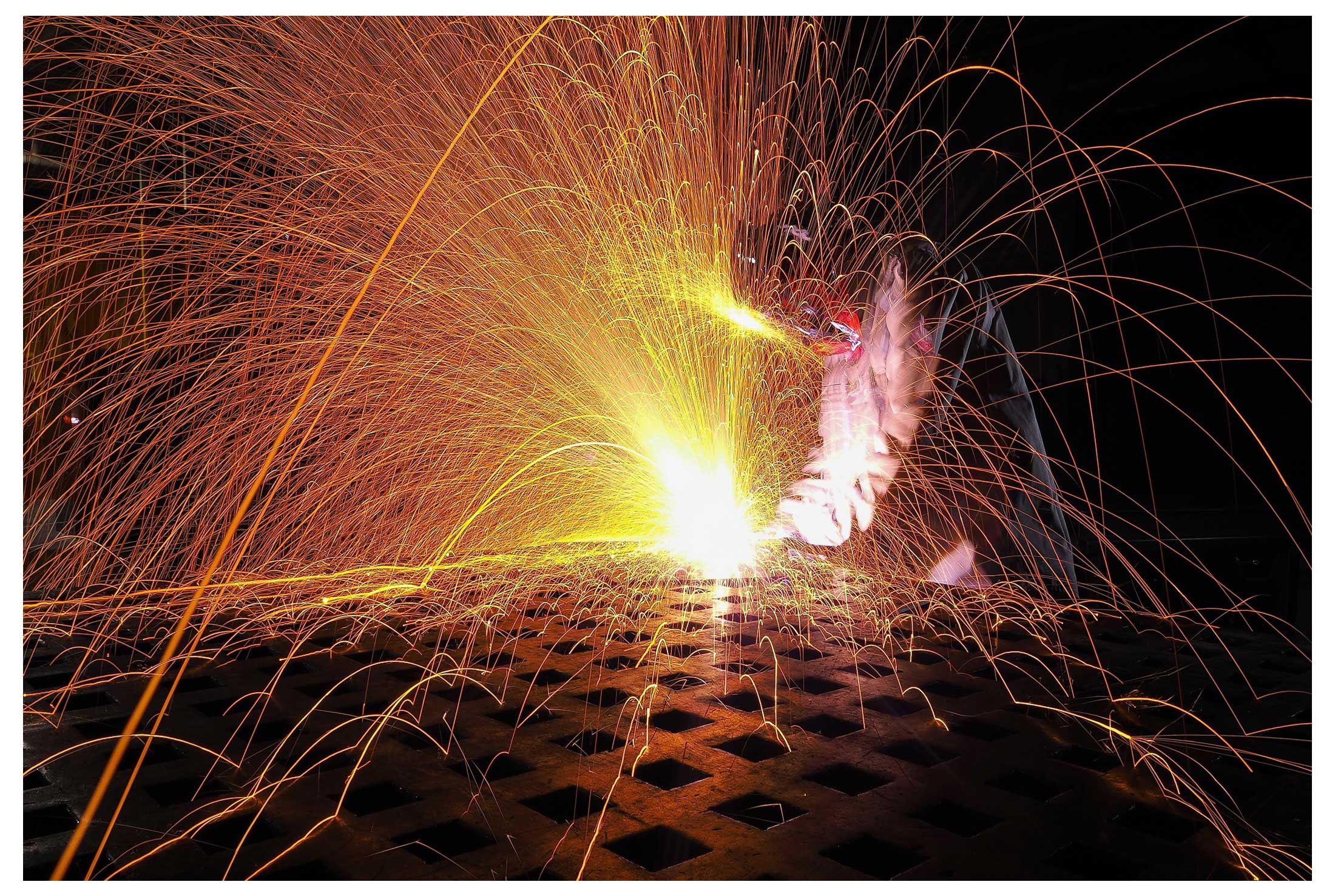

In oxy-fuel cutting, a torch is used to heat metal to its kindling temperature. A stream of oxygen is then trained on the metal, burning it into a metal oxide that flows out of the kerf as slag.

The advantages of Oxyacetylene Welding/Cutting

Oxyacetylene Welding Is Easy to Start

Most welders need a tool on hand for cutting metal, and an oxyacetylene torch is an affordable way to kill two birds with one stone. By setting up a cutting torch for welding, you can add a filler rod or just rely on the heat of the process to join the metal. Most importantly, a torch welding setup can help you accomplish all sorts of projects: welding, heating, brazing, and bending. You can work with carbon steel, chromoly, aluminum, stainless steel, and even cast iron. That’s not a bad range of options!

Portability and Heat for Welding

The oxyacetylene welding process can come in especially handy when you need to crank up the heat. While Multi-process welders and stick welding machines are coming in lighter packed with more power, thus oxyacetylene welding has historically been the first choice of welders. Simple setup allows welding anywhere.

Welding Cars and Machines with Oil Leaks

The regular users of oxyacetylene welding have praised its effectiveness for welding cars and trucks where there are oil soaked castings in crankcases and transmission housings. While arc welding will draw more heat to the surface and contaminate the weld, oxyacetylene will be more effective at joining the metal without applying excessive heat into the weld. This will minimize the amount of oil in the weld itself.

Of course many automotive welding jobs will require heating and bending of metal, so a torch setup can serve the dual purposes of heating and welding all in the same project.

With CanGas® onsite PSA Oxygen generator, your realtime oxygen supply at user spot for cutting or welding will be guaranteed anytime and anywhere.

Recommended Products