Waste Water/Sewage Treatment/Hatcheries

Globally, a steady rise in thedemand of fresh water and the ongoing depletion of usable natural resources, due to rapid urbanisation and economic development, are placing agrowing pressure on existing reserves. Water is a precious and increasingly scarce commodity. To tackle the scarcity challenge, the world needs more sustainable, effective water and waste water management practices and technologies.

Globally, a steady rise in thedemand of fresh water and the ongoing depletion of usable natural resources, due to rapid urbanisation and economic development, are placing agrowing pressure on existing reserves. Water is a precious and increasingly scarce commodity. To tackle the scarcity challenge, the world needs more sustainable, effective water and waste water management practices and technologies.

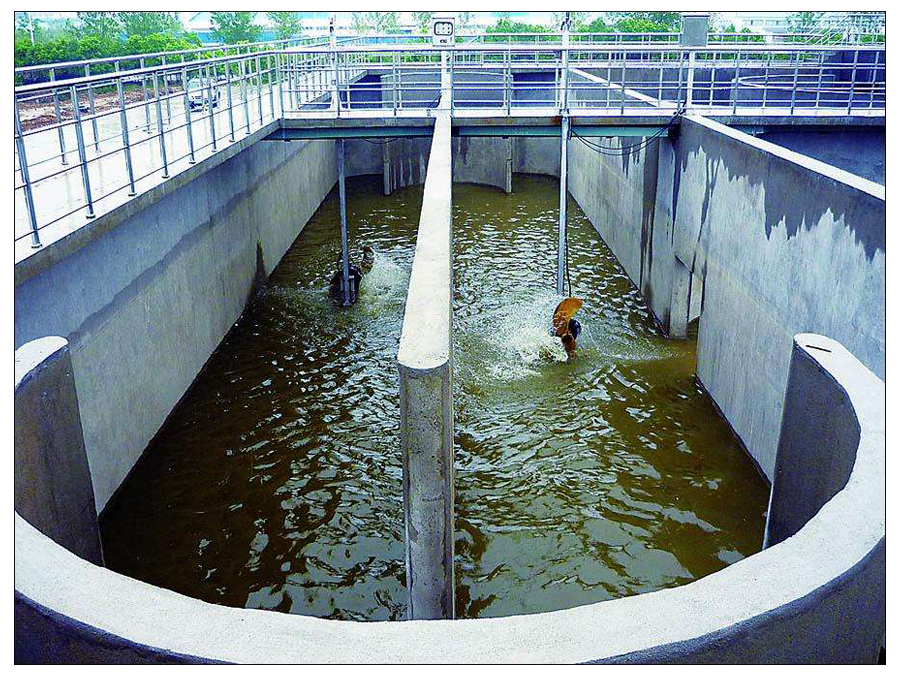

Waste water biological treatment process uses microorganisms to collect the suspended solids, to dissolve organic ones and to stabilize the organic matter. In addition waste water biological treatment removes or stabilizes nutrients such as Nitrogen and Phosphorus, which can stimulate growth of aquatic plants. The survival and relative growth of the various species of microorganisms depends on environmental conditions existing in the liquor. The most important ones are the quantity of food and nutrient, pH, temperature and Oxygen availability in the liquor.

Dissolved oxygen plays a very important role in water treatment. Some of the compounds in the sewage are biodegraded under the action of aerobic bacteria, and the dissolved oxygen in the water is consumed. The dissolved oxygen should be kept at a certain concentration, and in the aerobic process of the buried domestic sewage treatment equipment, the dissolved oxygen in the water is constantly supplemented due to the dissolved oxygen in the air and the photosynthesis of the green aquatic plants. But when the water body is polluted by the organic matters, the oxygen consumption is seriously increased, and if the dissolved oxygen is not added in time, the anaerobic bacteria in the water body will rapidly propagate, and the organic matters cause the water body to be blackened, however the concentration of dissolved oxygen shall be controlled, because if too high, the transfer rate of the oxygen is reduced, the power cost of the buried domestic sewage treatment equipment is increased, the peroxidation of the activated sludge is caused, the sludge is not flocculated, and the sedimentation effect of the flocculation body is affected.

Dissolved oxygen plays a very important role in water treatment. Some of the compounds in the sewage are biodegraded under the action of aerobic bacteria, and the dissolved oxygen in the water is consumed. The dissolved oxygen should be kept at a certain concentration, and in the aerobic process of the buried domestic sewage treatment equipment, the dissolved oxygen in the water is constantly supplemented due to the dissolved oxygen in the air and the photosynthesis of the green aquatic plants. But when the water body is polluted by the organic matters, the oxygen consumption is seriously increased, and if the dissolved oxygen is not added in time, the anaerobic bacteria in the water body will rapidly propagate, and the organic matters cause the water body to be blackened, however the concentration of dissolved oxygen shall be controlled, because if too high, the transfer rate of the oxygen is reduced, the power cost of the buried domestic sewage treatment equipment is increased, the peroxidation of the activated sludge is caused, the sludge is not flocculated, and the sedimentation effect of the flocculation body is affected.

In the natural condition, the oxygen content in the air is not much, and water temperature is the main factor, the lower the water temperature, the higher the content of dissolved oxygen in the water. The molecular oxygen dissolved in water is called dissolved oxygen, usually as do, expressed in the number of milligrams of oxygen per liter of water. The amount of dissolved oxygen in water is an index to measure the self-purification capacity of the water body. The dissolved oxygen value is a basis for studying the self-cleaning ability of water. The average dissolution concentration should be kept at 2 mg/l, and the activated sludge can be kept in good condition and the best state.

By injecting oxygen into your sludge plants, you can improve sludge settling, lower sludge load, and improve purification capacity. These improvements result in lower waste water levies and odorless purification, eliminating the danger, expense, and logistical problems of liquid oxygen deliveries. CanGas® onsite PSA oxygen generator ensures qualified oxygen supply to assist the whole process of water treatment system.

Typical users of CanGas® onsite PSA oxygen generator for ozone production in water treatment industry are Newland EnTech Co.,Ltd., Qingdao Guolin Environment Technology Company Limited, Qingdao AIKCAN Environment Technology Company Limited, Beijing Sumsun E.P. Hi-Tech Company Limited, etc.

For more information, please contact your Regional Sales Manager.

Related Products